Liquid Fertilizer Automation Loadout Upgrade

Liquid System Update Using Existing Mass Flow Meters and Weigh Tank

PROJECT: Crystal Valley Coop, Jackson, Minnesota

OVERVIEW

Automation upgrade on 2 liquid fertilizer bays to support up to 5 products.

WHAT THEY NEEDED

Crystal Valley was looking to modernize their 2-bay liquid fertilizer facility. The prior outdated system did not sync with nor offer the features of the other buildings that were running Kahler Automation software. They wanted to streamline the workflow process within the entire site to make it easy for staff to learn & operate within different areas.

WHAT WE DESIGNED

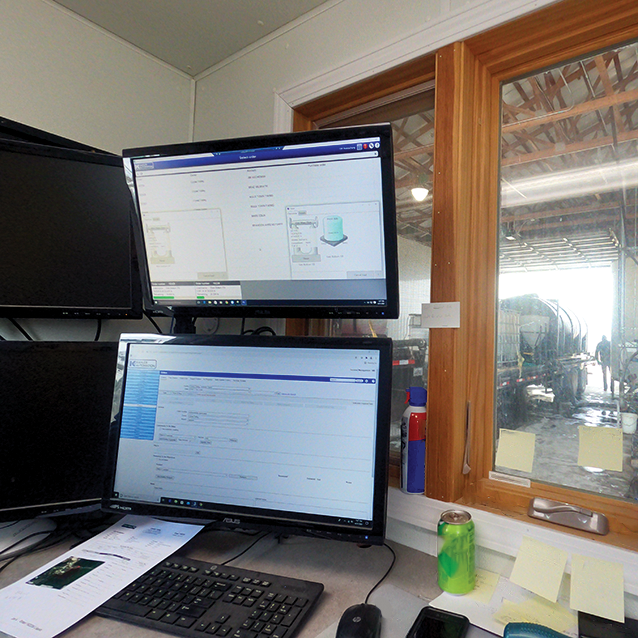

• Upgraded previous automation system with Kahler's preprogrammed touchscreen panel for ease of use

• Integrated with existing system components such as plumbing, meters, weigh tank, and solenoid panels

• Installed new automation control software in liquid, dry, and chemical buildings - site interconnectivity allows staffing flexibility and proficiency in each area

• Provided in-person hardware and software training to help staff be fully knowledgeable and skilled

WHAT THEY HAD TO SAY

Interview with Jesse Malchow, Regional Operations Manager, Crystal Valley Coop, Jackson, MN

Q: How has productivity improved with Kahler, compared to how things worked previously?

“Very efficient while we are in-season, very clean, very streamlined, loving the recordkeeping to be able to track inventory. A lot of questions can be answered just simply by looking at the reports, so all that is very beneficial.”

Q: What does having Kahler as a common system across locations allow you to do?

“Labor shortages are huge and we've been able to shift help from location to location and fill in when needed, and it’s all streamlined. The whole division is under Kahler so they can basically pick up where they left off no matter what location they are working out of. It’s very nice that way.”

Q: What are the benefits of having Kahler Automation software in all three of your buildings in Jackson?

“Super mainstream and paperless for administration, putting work orders together, loading trailers... its a beautiful thing.”